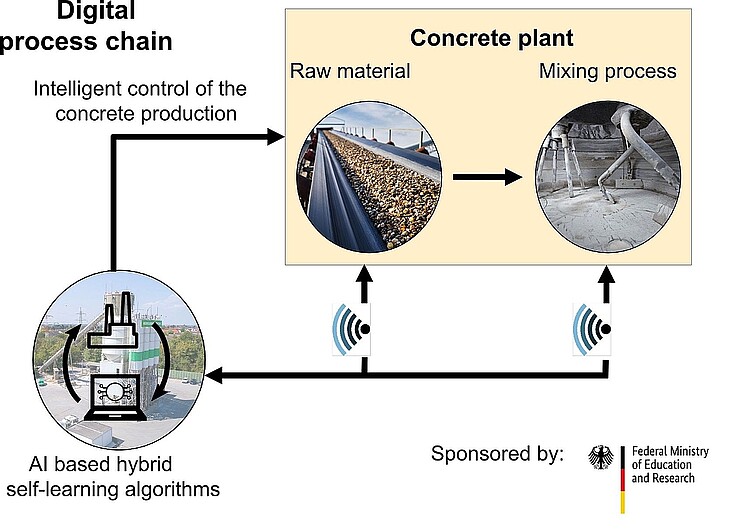

ReCyCONtrol - Self-learning control methods for an automatic production of robust and eco-friendly concretes

| Team: | M. Meyer, A. Ponick, A. Langer, C. Heipke, M. Wiggenhagen |

| Year: | 2021 |

| Funding: | Federal Ministry of Education and Research |

| Duration: | Since 2021 |

| Further information | https://www.recycontrol.uni-hannover.de/en/ _blank |

Concrete is one of the most widely used building materials in the construction industry - in Germany alone, several million tons of concrete are mixed and used every year. In order to preserve natural resources, demolition material (concrete, masonry, rock) from the dismantling of structures can be reused in concrete production in the form of recycled aggregates. A challenge here is the fact that the properties of the recycled mineral demolition materials vary extremely and thus may have a negative impact on the new concrete, especially on the fresh concrete properties (workability, segregation tendency). If the properties of the newly mixed concrete could already be determined during its production, it would be possible to counteract this directly with suitable methods. The ReCyCONtrol research project, funded by the German Federal Ministry of Education and Research, aims to achieve this control.

One part of the project is the observation of the concrete mixing process by using optical measuring sensors. The aim is to evaluate the flow behavior of the concrete in real time and thus predict its rheological properties (e.g. viscosity and yield point). On basis of these data, the concrete can then be specifically adjusted to the desired properties, e.g. by the use of suitable additives. This process is intended to be automatic and self-learning.

Since it is assumed that much information can be derived from the three-dimensional data of the flowing concrete, a stereo camera system is used. Deep learning is used to determine the fresh concrete properties based on regression. A Convolutional Neural Network (CNN) learns features of a recorded image sequence. In this approach, different scenarios are investigated: (a) In a two-step process, first the 3D surface of the concrete is computed from the captured stereo image sequences using classical image mapping methods as a function of time. Then, both the captured image sequences and the computed 3D information are used as input data for the CNN. (b) The network implicitly learns the 3D surface information relevant to the regression by itself, using only the stereo image sequences as input to the network. Since less information is given as input data in this model and more must be self-learned, more training data tends to be needed. (c) As a control for the relevance of the 3D information, the images from only one camera are used and thus monoscopic image sequences are used in the training. (d) As a control for the relevance of the time information, the images from only one time point are used in the training and no image sequences are used. If necessary, further information, e.g. results from optical flow calculations, can be added.